Tepid Water Heater for Emergency Fixtures

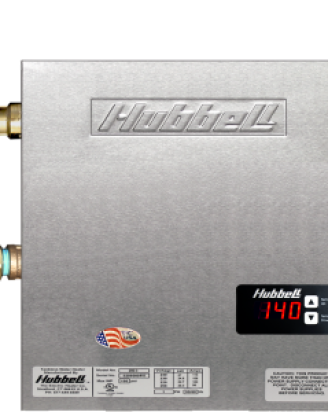

Hubbell Suretemp EMV

Specifically designed to provide high volume tepid water for emergency fixtures.

Configurable using electric, gas, steam or hydronic

Description

A heavy duty, reliable source for tepid water delivery

The Hubbell Suretemp EMV water heater is a packaged system designed to meet the requirements of ANSI/ISEA Z358.1-2014 for tepid water delivery to an emergency drench system. The water heater is factory piped and packaged with a mixing valve specifically designed, tested and proven for use in emergency safety shower/face/eyewash applications.

Features

Long lasting. HydraStone cement lining improves the longevity of the tank.

Dependable. The factory piped and packaged mixing valve is specifically designed for emergency safety drench systems and helps simplify installation.

Cost efficient. With 3" foam insulation, stand-by heat loss is reduced by over 24%, providing a highly efficient and economical solution.

Peace of mind. The dial gauge provides visual indication of water temperature and pressure.

• Reduces the risk of Legionella because water is stored at an elevated temperature

• Copper-silicon alloy tappings and high impact composite jacket cannot rust or corrode

Applications

Designed specifically for tepid water delivery to an emergency drench system, typically used in industrial facilities such as oil refineries, nuclear power plants, chemical/petrochemical facilities, fertilizer plants, manufacturing and wherever safety washing is required.

The Importance of Tepid Water

Benefits of a tepid water safety shower/eyewash station

An emergency tepid water shower and/or eye wash are critical and required in most industrial facilities. Tepid water, which is water that is neither too hot nor too cold, is defined as water between 60°F (16°C) and 100°F (38°C) and recommended by safety standards such as ANSI Z358.1-2014.

In an emergency, once an employee is exposed to chemicals or other hazardous materials, using water that is too hot or too cold for decontamination can exacerbate the situation:

• If the water is too hot, it can scald the person, causing additional injury and pain.

• If the water is too cold, it can cause shock and hypothermia, which can also be dangerous.

Tepid water helps ensure that a person can remain under the shower or eye wash for the recommended amount of time, which is typically 15 minutes. If the water is too hot or too cold, the person may not be able to tolerate it for the recommended time, which can result in incomplete decontamination.

Overall, the use of tepid water in an industrial emergency shower and eye wash is essential for ensuring the safety and well-being of the person using it. It helps to prevent further injury, allows for adequate decontamination, and complies with multiple safety standards.

Mixing Valve Features

Packaged with the Hubbell Suretemp EMV is a triple redundant, thermostatic pressure balanced valve designed specifically for emergency safety shower/face/eyewash applications. The valve is factory mounted and piped to the water heater.

Operational Features

• The mixing valve meets OSHA and ANSI requirements and provides constant 85°F tepid temperature output, regardless of inlet pressure and temperature variations. 85°F is ideal because it is not warm enough to open skin pores and not cold enough to deter usage.

• The EMV can achieve the high-volume demand required for a safety drench system by mixing the 170°F water in the tank with incoming cold water.

• The temperature setting is tamper proof and cannot be inadvertently adjusted in the field.

• The valve provides a full range of flows from the smallest flow of 0.4 GPM for an eyewash, to the combined 23 GPM flow for a simultaneous demand of shower, eyewash, and face wash system.

Safety Features

The mixing valve incorporates a pressure sensing controller with a valve actuator that senses the water pressure on both the hot and cold water inlet connections.

• If hot water pressure is not present, then the actuator overrides the mixing valve, and a flow of cold water is allowed.

• If no cold-water pressure is available at the mixing valve inlet, then the hot water port will close to prevent overheated water from exiting the mixing valve.

• The valve also includes a safety override feature that continuously senses the final mixed water temperature.

• If the final water temperature is overheated, the valve automatically closes the hot water port and fully opens the cold water port.

Safety Standards

OSHA 29 CFR 1910.151 states the following:

When the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.

ANSI/ISEA Z358.1-2014 states the following:

This standard establishes universal minimum performance and use requirements for eyewash and drench shower equipment used for the treatment of the eyes, face, and body of a person who has been exposed to hazardous materials and chemicals. Delivered flushing fluid temperature in an emergency system should be tepid. The standard defines a tepid water range of 60°–100°F. This standard also establishes minimum flow requirements at 30–90 PSI and use requirements for eyewash and shower equipment for the emergency treatment of the eyes or body of a person who has been exposed to injurious materials.

• The shower must have a minimum of 20 GPM at 30 psi for 15 minutes of controlled flow

• The eyewash must have a minimum of 0.4 GPM at 30 psi for 15 minutes of controlled flow

• The eye/face wash must have a minimum of 3.0 GPM at 30 psi for 15 minutes of controlled flow

• Units must meet all individual performance requirements when all components are operated simultaneously

The Hubbell Suretemp EMV satisfies OSHA and ANSI/ISEA tepid water requirements

• The EMV provides high volume tepid water for safety drench systems by integrating a specially designed mixing valve with a high-quality cement lined electric storage water heater.

• The EMV is designed to maintain 119 gallons of water at 170°F. This volume of water at this temperature is necessary to achieve the final flow rate of 23 GPM for 15 minutes of tepid water.

• When an emergency drench apparatus is used, the integrated mixing valve blends 170°F water from the tank with incoming cold water to achieve a continuous flow of 85°F tepid water. For 30 GPM shower heads the Hubbell EMV will provide 75°F water for 15 minutes.

Specifications

Note: Alternate storage capacities are available for smaller or larger requirements. Please consult factory for sizing requirements.

FAQs

Do I need to install an insulation blanket?

No. Most new electric water heaters are highly efficient with respect to the amount of heat loss radiating from the storage tank. This is due to the use of “blown in” polyurethane foam insulation as the insulating method for modern tanks, compared to the fiberglass blanket style insulation used by water heater manufacturer’s largely in the past. As such there is little to no benefit, and very possibly a detrimental effect to efficiency, installing an insulation blanket on a new electric water heater constructed with foam insulation.

What is the average life of an electric water heater?

The most important factor related to the life expectancy of a water heater is the quality and type of storage tank. On an average the life expectancy of a glass lined electric water heater is about 10-12 years (according to the National Association of Home Builders 2007 Study of Life Expectancy of Home Components http://www.nahb.org/fileUpload_details.aspx?contentID=99359 ), compared to a cement lined electric water heater’s average life expectancy of 23-26 years (Independent study of over 25,000 installations for an Electric Utility). Of course, there are various other factors that affect longevity including pressure fluctuations, usage, water conditions, environmental conditions, etc.

Is it OK to use softened water with my cement lined tank?

Yes it is OK. A water softener system will not affect the longevity or operation of a Hubbell cement lined water heater tank. A water softener is typically installed when a potable water system has hard water resulting in the need to soften the water. Unfortunately, the salt used in a water softener corrodes the anode rod and exposed steel surfaces of the water heater tank, rapidly causing a glass lined water heater to corrode and leak within a few years. This is an issue for a glass lined water heater due to its reliance on a sacrificial anode, however because a cement lined tank does not use a sacrificial anode softened water is of no concern to the Hubbell cement lined tank.

What is a sacrificial anode and does a cement lined tank need one?

All water heaters constructed using a steel tank requires a lining to protect the internal steel surfaces from corrosion. Certain linings (i.e. glass and epoxy), due to their nature, have unavoidable holes and imperfections resulting in exposure of the steel tank. As a result of this deficiency, the manufacturer will install an anode rod(s) in an attempt to delay corrosion of the steel tank. An anode rod is typically made of aluminum, magnesium or zinc, is a maintenance item that requires periodic inspection and replacement, and is often times the cause of a “rotten egg” odor to your hot water. Often referred to as a sacrificial anode rod because, over time, it slowly dissolves, sacrificing itself as it is attacked by aggressive substances in the water which would otherwise attack the steel tank through the pinholes and imperfections of the glass or epoxy lining. A cement lined steel tank on the other hand does not require an anode because of the thickness and guaranteed 100% coverage of the cement lining over all internal surfaces of the steel tank. This eliminates the need for an anode rod in a cement lined water heater, resulting in a significantly longer life compared to a glass or epoxy lined water heater. For a further discussion please click on the following link Cement Lining

What is the max water temperature setting?

The Hubbell cement lined tank is suitable for storing water up to 194°F. However, it should be noted that your water heater will likely require optional control accessories to achieve this temperature, but there is no concern regarding the ability of the lining to withstand this temperature. Additionally, there are numerous safety concerns that must be considered when storing water at elevated temperature, please consult factory.

Is there a cold water dip tube in the Hubbell tank?

Not exactly. The Hubbell cement lined tank includes a cold water diffuser integrated into the cold water connection which allows incoming cold water to be introduced into the tank in a controlled and non turbulent manner, thus avoiding premature mixing of cold water with the hot water in the tank. On Hubbell cement lined tanks the cold water inlet/diffuser is located on the side in the lower portion of the tank. Therefore, a Hubbell cement lined tank does not require a long dip tube extending all the way from the top to the bottom of the tank as is common in glass lined tanks.

How does my water heater ship?

All Hubbell storage type water heaters ship via common carrier and are classified by the Commodity Classification Standards Board under National Motor Freight Classification (NMFC) class 100. Each water heater is palletized and wood crated. All Hubbell tankless water heaters, when transported using common carrier, ship class 77.5. To provide the lowest transportation cost, in most cases the shipment is made on Hubbell’s account and the freight cost is added to the invoice, commonly referred to as “Pre pay and add”. For very large shipments, the most economical method (LTL or Dedicated Truck) for transporting the water heaters to the final destination will be analyzed by Hubbell's transportation department.

Why is Hydrastone Cement a better choice over glass lining?

Cement lining provides guaranteed 100% coverage with a minimum thickness of 0.5” over all internal tank surfaces. In comparison, glass lining is approximately 0.005” thick and includes imperfections, pinholes and variation in coverage thickness resulting in portions of unprotected steel tank exposed to corrosion. In an attempt to compensate, glass lined tanks include a sacrificial anode in an effort to slow down the corrosion of the tank. Cement lined tanks on the other hand do not require an anode due to the integrity of the lining. As such, a cement lined tank will far outlast a glass lined tank. For a more complete explanation of the benefits of the Hubbell cement lining please click on the following link Cement Lining

Why is a cement lined tank a better choice than stainless steel tank?

In almost all cases, a cement lined steel tank is a more robust tank compared to stainless steel. The weakness of a stainless steel tank is in the materials susceptibility to SCC (Stress Corrosion Cracking) caused by chlorides, bromides, iodides and fluorides in the water. The combination of residual stresses from welding, roll forming and stamping, and the cyclic stress from operating in a hot water system are sources of tensile stress, that when above a certain threshold stress, will make a stainless steel water heater tank susceptible to stress corrosion cracking. Cement lined steel tanks are not susceptible to this condition, and therefore are more resistant to corrosion and withstand the pressure and temperature cyclical operation of a water heater.

Is this model approved by Massachusetts?

| MA Plumbing Approval Number | Hubbell Model | Expiration Date |

|---|---|---|

| P3-0914-61 | HD, J, V, PS, SLN, T | 9/3/2017 |

| P1-1114-201 | EMV, CR, R, JTX, ETX, TX | 11/5/2017 |

| P3-0813-66 | CE110, SE, E, HE, SH, H | 8/7/2016 |

| G1-0813-4 | GX, DGX, JBX, JGX, CX | 8/7/2016 |

What is the formula to determine how much hot water I need?

To solve for the percentage of hot water to final mixed (i.e. tepid) water use the following equation. Cold Water ("C") is the temperature of water feeding the Hubbell model EMV heater. Hot Water ("H") is the temperature of water stored in the Hubbell model EMV heater. Mixed water ("M") is the temperature of the Tepid water that exits the Hubbell mixing valve. FORMULA: M-C divided by H-C = % of Hot Water to final Mixed water. For example, determine the percent of of 170F hot water required for a mixed (i.e. tepid) supply of 85F water when the cold water supply is 50F. 85-50 = 35 170-50 = 120 35 divided by 120 = 0.29 Therefore, 29% of the mixed 85F water must be 170F.

What temperature is tepid water?

Hubbell has designed its safety shower water heater to provide as standard 85°F tepid water, although 75°F is available as an option. In the ANSI /ISEA Z358.1-2009 American National Standard for Emergency Eyewash and Shower Equipment standard, tepid water requirements are in the Definitions section and are clearly defined as water ranging between 60°-100°F. ANSI defines "tepid water" as "A flushing fluid temperature conducive to promoting a minimum 15 minute irrigation period. A suitable range is 16-38°C (60-100°F)". Medical professionals recommend that tepid flushing fluids be used to treat chemically injured eyes and body tissue. Temperatures that exceed 100°F can enhance chemical interaction with the eyes and skin. Conversely, water temperatures below 60°F can cause hypothermic shock. The ANSI Z358.1-2009 standard states that while cooler flushing fluids may provide immediate relief after chemical contact, “prolonged exposure to cold fluids affects the ability to maintain adequate body temperature and can result in the premature cessation of first aid treatment”.

Is 277 volt 3 phase voltage available for a water heater?

For all water heaters 277V is only an available option in 1PH, not 3PH. The 277V 1PH voltage is a derivation of your existing 480V 3Ph power. Where 480V is the line to line voltage on a 3 phase system and 277V is the voltage from any one of these lines to neutral, thus making the 277V power available in 1PH only.

What is the R value of a Hubbell water heater?

Hubbell uses a blown-in polyurethane foam insulation for all cement lined water heaters and tanks up to 150 gallon capacity. This insulation has an R value of 7.2 per inch. Most Hubbell tanks have a minimum of 2 inches of insulation resulting in an R value of 14. Certain models are available either standard or as an option with 3 inch insulation and therefore have an R value of 21. Large storage water heater tanks over 150 gallon capacity and custom made stainless steel or alloy tanks have either 2" or 3" fiberglass insulation with an R value of 3.5 per inch.

Why Hubbell recommends 300 series versus duplex stainless steel?

While it is true that duplex stainless steel typically offers higher strength and resistance to Stress Corrosion Cracking (SCC) and chloride corrosion compared to austenitic (300 series) stainless steel, there are other factors that ultimately make it a less desirable choice compared to 300 series stainless steel. Duplex stainless steel makes up only 1% of the stainless steel market making it less readily available and higher cost especially in flanges, fittings and formed parts such as tank heads. While it is commonly stated that this added expense is offset by the ability to use material that is thinner due to the higher strength, this only applies to very large tanks where a reduction results in using a lower common plate thickness. As an example, a thickness reduction of 25% for a tank that is 3/16" thick in 300 series stainless steel still results in using the common 3/16" thick plate size in duplex stainless steel. The higher strength of duplex also has the negative result of decreased formability and machinability, adding cost to the fabrication and production process. In terms of welding, duplex stainless steel presents many problems in maintaining the proper two phase mixture which commonly leads to issues in the Heat Affected Zone (HAZ) such as loss of corrosion resistance, toughness, and post-weld cracking. This is true in all duplex stainless steel welding processes including TIG, MIG and Laser. By comparison the process of welding austenitic stainless steel is much more forgiving. The main weakness of austenitic stainless steel is its susceptibility to Stress Corrosion Cracking (SCC) and chloride corrosion. Three factors that all must all be present cause this type of corrosion: elevated heat, the presence of chlorides, and residual stresses. In water heaters elevated heat and the presence of chlorides cannot be controlled. However, post-weld heat treating in a vacuum furnace followed by cooling in an inert atmosphere relieves the residual stresses in austenitic stainless steel tanks and therefore eliminates the susceptibility to this corrosion. For this reason, this post-weld heat procedure is performed on all Hubbell stainless steel tanks. The heat treating process is highly controlled and verifiable, unlike the difficult to control process of welding duplex stainless steel. Therefore, Hubbell offers stainless steel tanks fabricated from the 300 series (typically Type 304L or 316L) only, as this is a far more proven and verifiable material and fabrication process which will result in longer tank life. Of course, an alternative option is to specify the Hubbell cement lined steel tank which also provides a considerably longer life and is a more economical solution compared to duplex stainless steel and 300 series stainless steel.

Do Hubbell water heaters qualify as Low Lead?

Yes, all Hubbell water heater models qualify as meeting the low lead requirements of the “Reduction of Lead in Drinking Water Act” amendment to the “Safe Drinking Water Act” (SDWA) Section 1417(d) effective as of January 4, 2014. Hubbell certifies that its water heaters meet the following requirements of the SDWA and therefore are qualified and certified as Low Lead : (a)Hubbell water heater do not contain more than 0.2 percent lead with respect to solder and flux (b)Hubbell water heaters do not contain more than a weighted average of 0.25 percent lead with respect to all wetted surfaces of the water heater

Can my cement lined tank be damaged during installation and handling?

Although we don’t advocate dropping our tanks sometimes stuff happens. The Hubbell Hydrastone cement lining is a minimum of 1/2"thick (100 times thicker than a glass lined tank) and is guaranteed to uniformly cover 100% of all internal tank surfaces. Basically the Hubbell cement lining is a tank within a tank and should have no problem withstanding the rigors of shipping and installation. Although not necessry, you can specify an optional hand hole on our smaller tanks (150 gallon and under) to provide a means for inspection and repair. Water heaters with tanks larger than 36" generally include a 12" x 16" manway. In both cases, a Hubbell tank properly maintained will last decades.

What is the difference between solid-state and electromechanical relays?

Depending on the application, one switch may be more advantageous than the other. Please refer to this article to read more about the differences between solid-state and electromechanical relays.

What is ANSI Z358.1-2009?

The Hubbell safety shower water heater is specifically designed to provide tepid water that meets the requirements of the ANSI Z358.1-2009 Standard for Emergency Eyewash and Shower Equipment. This standard clearly defines tepid water as ranging between 60°-100°F for the purpose of acting as "A flushing fluid temperature conducive to promoting a minimum 15 minute irrigation period. A suitable range is 16-38°C (60-100°F)". Medical professionals recommend that tepid flushing fluids be used to treat chemically injured eyes and body tissue. Temperatures that exceed 100°F can enhance chemical interaction with the eyes and skin. Conversely, water temperatures below 60°F can cause hypothermic shock. The ANSI Z358.1-2009 standard states that while cooler flushing fluids may provide immediate relief after chemical contact, “prolonged exposure to cold fluids affects the ability to maintain adequate body temperature and can result in the premature cessation of first aid treatment”.

How do I prepare my water heater for long term storage?

The water heater must be stored in the orientation of intended use (vertical, horizontal). The recommended ambient air temperature range is between 50 and 105 degree F and not exceeding 65% Rh. Under no conditions should the unit be subject to freezing temperatures. The unit is intended to be stored indoors, protected from the elements. Desiccant material should be inserted into the electric control panel and heating element terminal house (if applicable). Prolonged storage will require periodic inspection of desiccant. For cement lined tanks only, place approximately 10 gallons of water in the tank before closing and sealing all openings to ensure a humid atmosphere for the lining is maintained. Cap and seal all openings and tank tappings and/or flanges. Provide the necessary protection to ensure the tank and all accessories are protected from physical contact that could result in damage. Shrink wrapping or other suitable protective plastic may be applied to the exterior. Start up and installation guidelines must be followed, with particular attention to testing of the electric heating element.

When is ASME code required?

Engineers and designers should consider all local codes when specifying approval requirements. For an in depth explanation, reference the National Board of Boiler and Pressure Vessel Inspectors Guide In general, water heater pressure vessels require ASME if the heat input exceeds 200,000 Btu/Hr (58.6kW) or if the storage capacity exceeds 120 gallons. Many water heater manufacturers choose to label and rate their tank 119 gallon to avoid any confusion. However, a tank rated at 120 gallons does not require ASME as code is only required for tanks that exceed 120.

What if I want to supply tepid water to more than one safety shower?

The amount of hot water required to supply tepid water per safety shower is 120 gallons. For two safety shower systems, specify the Hubbell model EMV240 which consists of two 120 gallon tanks mounted to a common skid assembly and factory piped with one mixing valve. Generally speaking, the optimal system design is to place the water heater as close to the safety shower as possible. If your system consists of more than two safety showers, you may want to consider installing one model EMV120 tepid water heater for each safety shower. Alternatively, a centrally located large storage tank (storage capacity sized at 120 gallons for each safety shower) with factory integrated mixing valve(s) may be specified to service a circulating loop. There are certain design challenges associated with a central system, Hubbell recommneds consulting with a Sales Engineer before selecting this method.

Is Legionella a concern for my system?

According to the World Health Organization, the temperature growth range for Legionella is between 68°F and 113°F, with the ideal growth range between 90°F and 108 °F. At 140°F, 90% of the bacteria is killed in 2 minutes and at 158°F, 100% of the bacteria is killed instantly. Below 68°F, Legionella is dormant (not reproducing) but is not killed and will begin reproducing once the temperature is raised. A tepid water recirculation loop will be subject to the growth of Legionella but continuous circulation significantly reduces stagnation and Legionella growth. With that in mind, the design of the Hubbell model EMV is better suited to minimizing the risk of Legionella compared to a water heating system that only heats the water to a tepid temperature due to the fact that the Hubbell EMV model heats the water in the tank to 170°F. As the recirculating water is sent to the heater, some of the return tepid water goes to the mixing valve and some is returned to the tank to be re-heated to 170°F. It is reasonable to believe that throughout the continuous cycle, all of the water will be returned to the vessel at some point to be re-heated thus killing any Legionella bacteria that was present. If Legionella growth is still a concern, the Hubbell model EMV is provided with an additional tapping at the hot water outlet prior to the mixing valve. This tapping can be utilized to send 170°F hot water throughout the system periodically to ensure the elimination of Legionella in the recirculation loop.

Can I install the Hubbell model EMV outdoors?

The standard EMV model is designed for indoor use only. However, optional construction including outdoor as well as hazardous location is available; please consult with a Hubbell Sales Engineer to discuss your application. Regarding outdoor installations, heat tracing for freeze protection of plumbing lines as well as an anti scald device to purge excessive temperature due to thermal gain (sunlight and ambient conditions) must be considered.

Why is a storage heater preferred over a tankless heater?

There are a number of factors that make a storage system more desirable than a tankless system for delivering tepid water to your safety shower. Infrastructure, pressure drop, reliability, and serviceability are the major areas where there is a significant difference between the two systems. Regarding infrastructure, a storage system is typically rated 6kw or less and a tankless system is typically rated around 150kw, a significant difference when considering wire and circuit breaker size and electrical demand, not to mention installation costs. A storage system can operate on either 1 or 3 phase power and draws at most 25 amp depending upon your power selection, whereas a tankless system is practical only in 3 phase power and draws 180 amps or more. Pressure drop through a storage system is less than 4 psi, whereas a tankless system is likely to result in a pressure drop of 15 psi or more, potentially resulting in insufficient flow through the safety shower. With respect to reliability, a storage system utilizes well proven and long fielded technology and is extremely reliable, not to mention the fact that because the system operates using stored hot water, you have visual positive verification that the system is fully hot and ready to provide tepid water before an emergency situation arises. A tankless heater on the other hand is in “standby” mode until such time that it is required. If the unit for some reason is inoperable or malfunctions, there is no way for an operator to know its status prior to an emergency event. This could be disastrous for an injured person, not to mention the facility owner, if a person is unable to properly wash down due to a malfunctioning or inoperable heater. Finally, because a tankless heater requires sophisticated controls to operate and control temperature, it has significantly more potential failure points compared to a storage system, making it not only less reliable but significantly more difficult and expensive to maintain and service.

Can I install the Hubbell model EMV in a hazardous location?

The standard EMV model is designed for indoor use in a non hazardous location only. However, optional construction is available for installation in a hazardous location. Please note you will need to provide your Hubbell Sales Engineer with specific information at the time of quote request regarding the hazardous location rating you require for your application including Class (I, II or III), Division (1 or 2), Group (A, B, C or D) and finally the Temperature Class (T1 thru T6).

What is the pressure drop through the Hubbell model EMV water heater?

At 23 GPM (the full flow of a 20 GPM safety shower and 3 GPM of a combination face/eyewash station) the pressure drop across the entire Hubbell EMV emergency safety shower water heater is less than 4 psi.

What is the annual operating cost?

The annual operating cost including standby heat loss and semi-annual performance testing is approximately $154 (based upon $0.12 per kWHr) annually. This assumes an ambient temperature of 50F and incoming cold water supply of 40F and two (2) full operational 20 minute performance tests performed annually.

If I lose power, will I continue to get tepid water?

Yes. This is one advantage of the Hubbell model EMV storage tepid water heater. Because the Hubbell tepid water heater design utilizes a storage tank, there is always a sufficient supply of hot water on standby and ready for an emergency fixture. Once the Hubbell storage tank achieves its set temperature, the unit will deliver tepid water even when there is a disruption of electric power to the heater (i.e. during an emergency).

Does the EMV have CSA approval for Canada?

The EMV is approved to UL Standard 1453 and CSA C22.2#110. ETL is our third part approval agency so you won’t find it listed with CSA the same way you won’t find it listed with UL. That doesn’t mean it is not approved to the UL or CSA standards it just means that they are not our third-party approval agencies.

Documents

Warranty

Hubbell shall warranty all electrical components against defects in workmanship and material for a period of one (1) year from date of start-up, and the heating chamber for a full five (5) years from date of start-up, provided that the unit is started within three (3) months of date of shipment and installed and operated within the scope of the heater's design and operating capability. Labor is not covered under warranty. Each heater shall be shipped with a complete set of installation and operating instructions including spare parts list and approved drawings.

Technical Support

Our Technical Support Reps are ready to assist you. Please contact us today.